Retail inventory management is about to be updated. The transition from 1D to 2D barcodes on consumer product labels enables firms to improve their operations in previously unimaginable ways. This move intends to improve product tracking by making it more efficient, accurate, and future-ready. Before delving into the specifics of its evolution, let us explain what it is, why it is significant, and the issues it faces today.

What is Retail Inventory Management?

At its foundation, retail inventory is the art (and often the hassle) of maintaining optimum stock levels. It’s about striking a fine balance between having enough products to match client demand and not having too much inventory.

Key Objectives

The system’s goals can be boiled down to three main points:

- Maintain Stock Availability: Nothing turns off a customer faster than hearing, “I’m sorry, we’re out of stock.”

- Prevent Overstocking: Keeping too much inventory consumes capital, takes up storage space, and puts your products at risk of becoming obsolete. Continuous inventory turnover ensures that products move through the system, reducing stagnation and allowing for fresh supply.

- Tracking stock movement: Having an idea of where your goods are, either in the warehouse or on the shelves at the stores, helps things run more efficiently.

Core Components

Good inventory management isn’t magic; it’s built on a few solid pillars:

Inventory tracking. It is crucial to monitor stock levels in real-time so that you do not have to guess when supplies will deplete. A well-planned safety stock is more than simply a precaution; it is your insurance against supplier disruptions and demand surges. A procurement management system can further streamline this by automating reordering, managing supplier relationships, and maintaining optimal stock levels while preventing overspending.

Replenishment: It is more than just responding to empty shelves. It is about forecasting demand and adopting proactive measures.

Reporting: The numbers tell the story. Data analysis helps businesses make better decisions, whether it’s determining which products sell the fastest or identifying seasonal trends.

Challenges in Inventory Management for Retail

No system is perfect. Even with 1D barcodes, retailers face persistent challenges:

- Keeping inventory balanced across online sites and stores in person is like juggling torches of fire—it is possible but difficult.

- Products don’t always arrive in pristine condition. Processing refunds and damages in a timely manner can put strain on operations.

- Traceability regulations, particularly in the food and pharmaceutical sectors, create another level of complexity.

The Current State of Inventory Management with 1D Barcodes

At a glance, 1D barcodes play a vital role in these key processes:

Stock tracking: It entails scanning products upon arrival, during transfers, and at the point of sale to ensure inventory records are up to date.

Scanning at Checkout: The familiar beep at the register indicates correct product identification for invoicing and stock adjustments.

Backend Reconciliation: From sales data to stock audits, 1D barcodes provide systems with the information they want for reporting and decision-making.

Shipping and Receiving: Package labels track things as they transit through the supply chain.

Repricing or Markdown Management: Stickers with 1D barcodes enable retailers to change prices while keeping product traceability.

Effectiveness of 1D Barcodes

- The enduring appeal of 1D barcodes lies in their simplicity and cost-effectiveness:

- They contain basic product information, which allows scanners to rapidly identify objects.

- The infrastructure—scanners, printers, and additional systems—is low-cost, easily accessible, and simple to operate.

- For retailers with simple requirements, 1D barcodes provide adequate functionality without adding excessive complexity.

Limitations and Challenges

Despite their utility, 1D barcodes come with notable drawbacks that are harder to ignore.

Limited Data Storage Capacity: A 1D barcode typically holds only a product identifier, requiring backend systems to house the associated data. This dependence can slow processes and create bottlenecks.

Scanning Vulnerability: Misalignment or damage to the barcode might result in errors or delays during scanning, which can spread throughout processes.

Built-in traceability not available: 1D barcodes cannot carry vital data such as batch numbers, expiry dates, or serial numbers. This makes compliance with traceability standards an arduous task, especially in the field of food and medicine. For a long time, 1D barcodes have worked without errors; however, their weaknesses are showing up openly when retail operations get more advanced and demanding.

What Can 2D Barcodes Do on Consumer Goods?

Think of the 2D barcodes as an inventory management tool that is Swiss Army knife of inventory management for retail. Unlike 1D barcodes that can store only a product identifier, 2D barcodes can contain any of the following:

- Batch numbers to trace the production process.

- Expiry dates to maintain the product’s freshness.

- Serial numbers to keep track of the product.

- URLs with product information, promotions, or recall notices, which directly lead the consumers to them, may also be involved in this regard.

This is a simple scenario: a lady that is very busy can use an application to read a GS1 digital link QR code on a baby food jar in a store. In a few seconds, the product is confirmed as not stale and was part of a safe production batch, even a link to the manufacturer’s sustainability pledge is provided. That’s not just convenience—it’s trust built into a simple scan.

What Stays Mostly The Same

The adoption of 2D barcodes does not necessarily mean that the previous playbook will be thrown out of the window. Some important mechanisms are persistent:

Inventory Tracking: The procedure of product scanning, the feedback on stock level, and the movement tracking is carried out as per the regular.

Backend Data Management: The method involved is still going to be a continuation of the process so you’ll proceed with merging all the scan data to do the reporting and the analysis. However, some systems may require modifications to handle bigger data quantities, decode 2D barcode formats, and sync with new programs that utilize the barcode’s expanded capabilities. Implementing a server side tracking solution can improve data accuracy and security by processing scan data rather than depending entirely on client-side scripting. In essence, the foundational workflows of the system don’t change; they’re simply enhanced.

What Improves

Enhanced Data Capacity: The product of tomorrow and the day after are no more. Now, barcodes can embed resources like lot numbers, expiration dates, and even web links for marketing, saving front-end systems.

Faster, More Flexible Scanning: Scanners should be aimed no more by the operator. GS1 QR codes are up-to-date in their reading perspective from various angles, which thus results in faster operation and correct readout.

Built-In Traceability: You can have the latest info at your fingertips. Retailers can now have access to crucial product details in a real-time manner.

Omnichannel Support: The codes are versatile covering both physical and even Internet-based platforms, and besides, they give rise to better and richer consumer interaction. Just visualize scanning a product at a store to see the reviews or make a refund by simply scanning it.

What Retailers Need to Upgrade to Accommodate the 2D Barcodes

Making a shift to 2D barcodes is similar to replacing a trusty car with an eco-friendly nice car—it definitely necessitates some changes, but the benefits for the long haul are significant. For this to happen successfully, retailers have to invest in areas that are crucial for the smooth adoption of this technology, and at the same time, they should also be well-equipped for the adoption of the best 2D barcodes. Let us find out what are these areas:

Equipment Upgrades

2D Barcode Scanners: At present, these innovative devices are capable of reading barcodes both 1D and 2D. Such kinds of scanners work faster and are more flexible, enabling them to decode codes from different perspectives and thus speed up checkout and storage processes.

Software Upgrades

The barcode is just as clever as the computer that reads it. Companies need to make sure that their inventory management software is capable of handling more data contained in 2D barcodes. The major developments that they can include:

Advanced Data Processing: Technological innovations in data processing such as the products to be decoded batch numbers, expiry dates, and serial numbers should not affect the speed of the machine.

GS1 Standards Integration: The correct GS1 barcode system in the program needs the program to follow the GS1 framework standard which is the one and the only one globally. Only by following this standard. You will be able to effectively communicate not only your business but also others along the supply chain in an efficient way whether you are local or abroad.

Employee Training

Mission-critical IT operations are using new tools which imply new processes. And your employees are the ones who have to be ready to learn these new tools. These training programs provided to your employees/staff will allow them to concentrate on:

- How to use the updated devices properly and the troubleshooting of the most common issues.

- Reading that symbol will inform you of the expiry dates if the items still have not expired and the batch codes for those that have. But there is still the matter of the workers knowing about these things when it comes to tasks like recalls or inventory audits.

- Today, 2D barcodes contribute to speed and efficiency in the process of entrepreneurship and thus workers are motivated to endorse the new system more.

A More Advanced GS1 QR Code Solution is here

Not every retailer is ready to overhaul their systems overnight. That’s why a great GS1 QR code generator is best to use for creating a hybrid labeling solution.

It can generate both types of barcodes on one label. Each product label includes a 1D barcode for legacy systems and a GS1-powered QR code with serial numbers for advanced functionality. This new approach serves as a connecting link between the two: the slow adopters who want to learn at their own pace and the old infrastructure whose functions can still perform well. In this way, retailers could exploit the benefits of 2D barcodes, such as the option to trace the products and thus the possibility to get richer and more valuable data while being compatible with their current structure. This can lead to time savings during the transition period.

The Future of Retail: Enhanced Inventory Turnover and Customer Experience

Inventory management in retail is at a crossroads. The transition from 1D to 2D barcodes involves more than just implementing new technology; it is also about developing to meet the needs of modern retail. Retailers who are the first to plan their inventory will not only keep stocks accurate but will also comply perfectly with the new regulations, thus involving impressionable “green” shoppers more and more in their activities. Change may require new equipment, software, and extra training, but in the end, you will say ‘Welcome’ to a system not only made for today’s adaptability but also tomorrow’s potential. It leads to a waste of money and time. On the other hand, timely modernization gives the assurance that one is well prepared for the challenges that come ahead. It is time to make the transition, not only to be comparable but to get ahead of the rest.

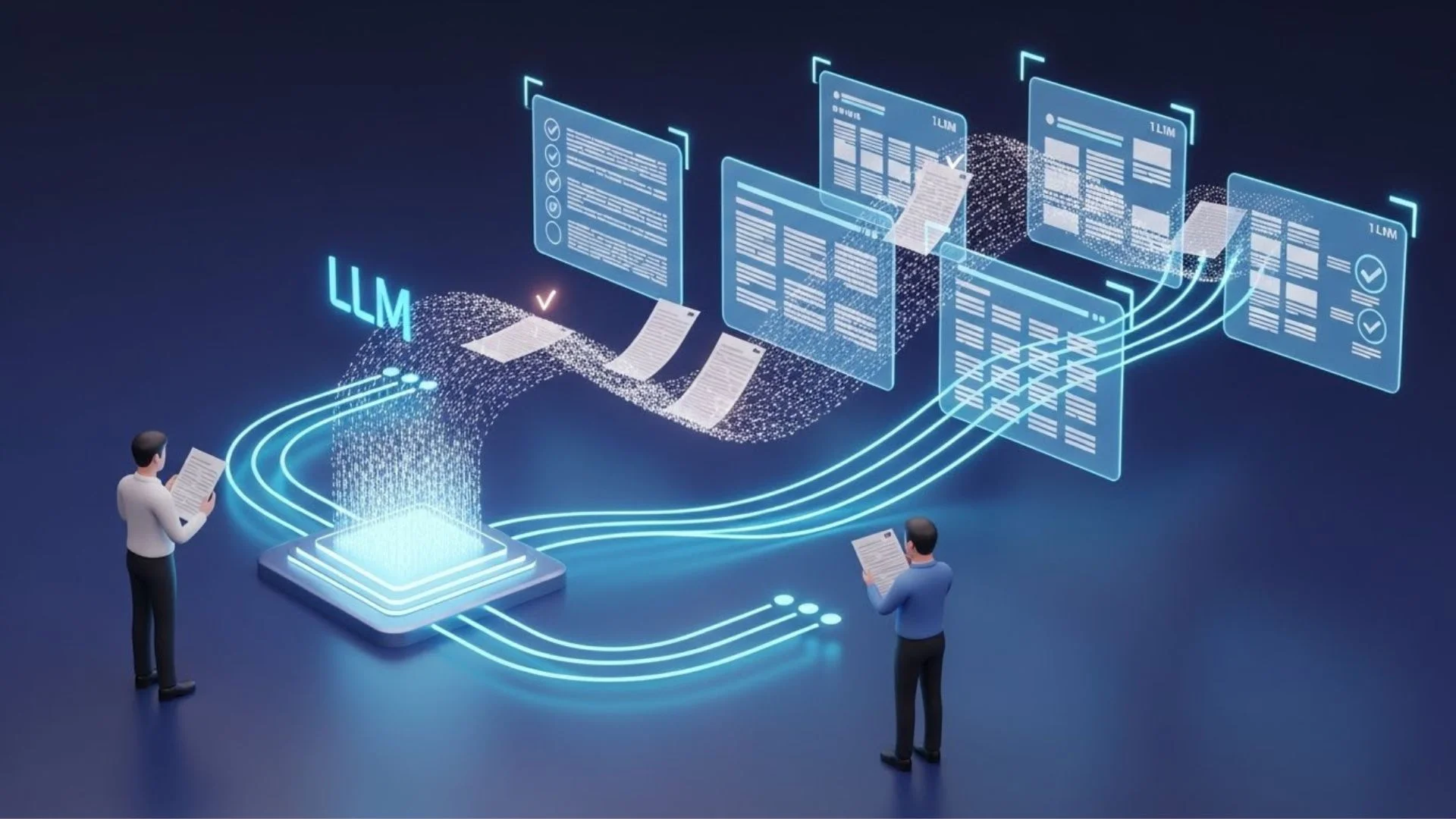

nandbox App Builder

Any company’s most important asset is inventory control, which guarantees correct and quick tracking of goods from the warehouse to the consumer. Good inventory control helps companies to minimize stockouts, lower extra inventory, and streamline supply chains. The nandbox App Builder lets companies design unique mobile apps without any programming, therefore improving this process. Businesses may quickly control inventory, monitor stock levels, and simplify ordering and delivery by means of the app. The nandbox platform’s strong features and easy interface enable companies to keep on top of their inventory by means of real-time updates and reports, so facilitating better operational efficiency and decision-making.