Top Eco-Friendly Benefits of 3D Printing

3D printing, including choose 3D resin printer, has emerged as a revolutionary technology with profound implications for various industries. One of the most significant advantages of 3D printing is its potential for sustainability. This technology addresses the critical question: is 3D printing environmentally friendly? In this article, we will explore the eco-friendly benefits of 3D printing. And even highligh how this technology contributes to a more sustainable future.

Reduction of Waste

Traditional manufacturing processes typically generate significant material waste. In contrast, sustainable 3D printing employs additive manufacturing techniques, constructing objects layer by layer. This method minimizes waste, as it uses materials only where needed. The precision of 3D printing sustainability significantly reduces excess materials, promoting a more efficient use of resources. Energy Efficiency

Eco friendly 3D printing is known for its energy efficiency. Traditional manufacturing often demands high energy consumption for processes. Such as cutting, drilling, and milling.3D printing. However, uses less energy since it directly constructs objects from digital models. The energy savings contribute to the overall sustainability of this technology, making 3d printing eco friendly and a preferable choice for environmentally conscious manufacturers.

Use of Sustainable Materials

A critical aspect of sustainable 3D printing is the use of eco-friendly materials. Sustainable 3d printing materials include biodegradable and recyclable options, which significantly reduce the environmental impact. For instance, 3d printing biodegradable materials like PLA (polylactic acid) are derived from renewable resources such as corn starch and sugarcane. These materials decompose naturally, unlike conventional plastics.

Reduction of Carbon Footprint

3D printing can also lower the carbon footprint of manufacturing. By producing goods locally and on-demand, 3D printing sustainability helps decrease the need for transportation and storage, which are major contributors to greenhouse gas emissions. The localized production model enabled by 3D printing supports a sustainable 3D printing approach, minimizing the environmental impact of logistics. Additionally, 3D printing often requires less material compared to traditional manufacturing methods, leading to reduced waste and energy consumption. This efficiency further contributes to a lower carbon footprint. By adopting 3D printing, industries can not only streamline production processes but also enhance their commitment to environmental stewardship, making it a vital tool in the fight against climate change. The reduction in transportation emissions and resource usage positions 3D printing as a key player in the move towards more sustainable manufacturing practices.

Design Flexibility and Resource Optimization

Recycling and Reusability

Recyclable 3D printing materials are another significant benefit of this technology. Materials like PLA and certain types of nylon can be recycled and reused in the printing process. This capability not only reduces waste but also supports a circular economy where materials are continuously repurposed. The ability to recycle and reuse materials makes 3D printing environmentally friendly and an ideal solution for reducing the environmental impact of manufacturing. Additionally, advances in 3D printing technology are continually increasing the range of materials that can be recycled, including metals and composites. This advancement enhances the sustainability of 3D printing, making it a more appealing choice for industries committed to green manufacturing. The QR Code Generator can further support these efforts by enabling manufacturers to attach QR codes that provide detailed recycling guidelines and material composition information, ensuring that products are reused or disposed of responsibly. By using recyclable materials, 3D printing reduces resource consumption and supports long-term environmental conservation.

Innovation in Sustainable Materials

The advancement of 3d printing organic material and other sustainable options continues to evolve. Researchers are constantly developing new materials that are both high-performing and environmentally friendly. These innovations include materials made from algae, recycled plastics, and other organic sources. The ongoing development of 3d printer biodegradable material ensures that 3D printing remains at the forefront of sustainable manufacturing practices.

Future Prospects of Eco-Friendly 3D Printing

The future of 3D printing in sustainable manufacturing looks promising as innovations continue to emerge. Researchers and developers are focusing on creating more efficient and eco-friendly 3D printers that consume even less energy and utilize renewable resources more effectively. For example, researchers are exploring solar-powered 3D printers and advancements in low-energy laser sintering techniques to further reduce this technology’s carbon footprint. As these innovations become more mainstream, the environmental benefits of 3D printing are expected to increase, cementing its role as a cornerstone of green manufacturing practices.

Applications in Various Industries

The versatility of 3D printing extends its eco-friendly advantages across a wide range of industries. In healthcare, for instance, 3D printing is used to create custom prosthetics and implants. This can reduce waste and the need for mass production. In the automotive and aerospace sectors, the ability to produce lightweight components with complex geometries contributes to fuel efficiency and reduced emissions. Even the fashion industry is benefiting from sustainable 3D printing, with designers using biodegradable materials to create eco-friendly clothing and accessories. These applications highlight the broad impact of 3D printing on promoting sustainability in diverse fields.

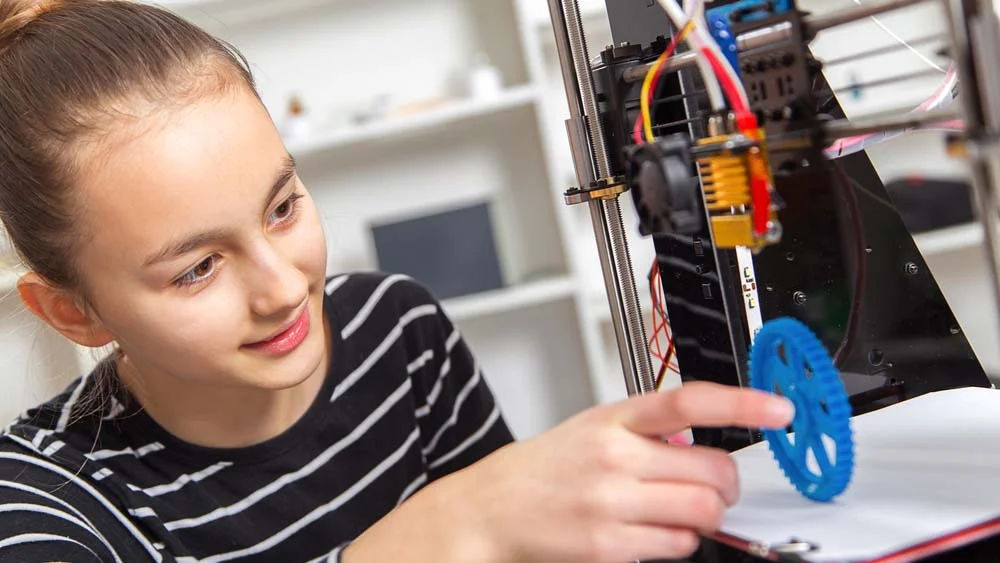

Education and Community Impact

Promoting sustainable 3D printing also has significant implications for education and community development. Educational institutions are increasingly incorporating 3D printing into their curricula, teaching students about its environmental benefits and inspiring the next generation of innovators to focus on sustainability. Additionally, community makerspaces equipped with 3D printers allow local entrepreneurs and hobbyists to experiment with eco-friendly manufacturing techniques, fostering a culture of sustainability. By empowering individuals and communities with knowledge and access to sustainable 3D printing technologies we can drive widespread environmental change and support the global transition towards greener practices.

Conclusion

The question of whether 3d printing sustainable can be answered with a resounding yes. The numerous eco-friendly benefits of 3D printing, like waste reduction and energy efficiency. Moreover, the use of biodegradable and recyclable materials, demonstrates its potential to revolutionize manufacturing in an environmentally friendly way. As technology continues to advance, 3D printing eco-friendly will become an increasingly integral part of sustainable production processes, driving innovation and reducing environmental impact.