OT asset management is crucial for maximizing ROI in industrial environments. In this chapter, we will explore various strategies and technologies used to enhance operational technology asset management.

This includes leveraging data analytics to improve operational efficiency, integrating IT and OT systems, predictive maintenance, and other methods to enhance operational efficiency and, ultimately, the bottom line.

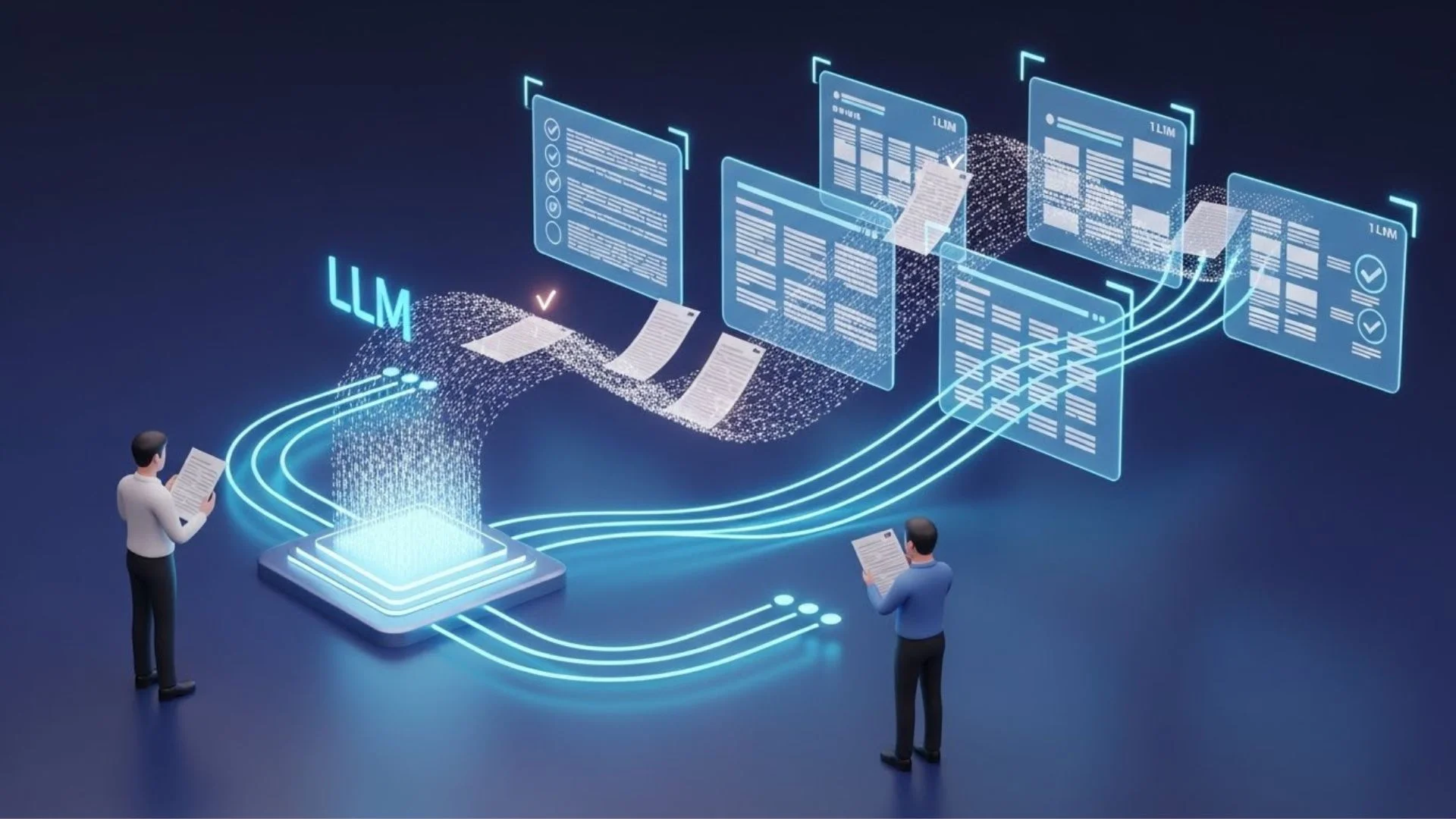

How Data Analytics Can Be Used in Leveraging OT Asset Optimization

First, it is important to collect and integrate data retrieved from OT assets. It is derived from various sources, including sensors, control systems, and other industrial devices transmitting real-time information about conditions and operations.

The main sources of data are sensors, control systems, and industrial equipment. Fundamental integration techniques include using IoT platforms and data lakes to centralize this information.

That’s the game-changing use of analytics in predicting maintenance needs and optimizing assets. Advanced analytics will help shift from a reactive to a predictive maintenance strategy that reduces asset-related downtime and prolongs its life cycle.

Predictive analytics forecast the needs of maintenance so that potential failures are avoided, while optimization algorithms improve asset use through data insights. While many companies have successfully integrated data analytics with their OT environments, only a few report significant benefits

A leading manufacturer trimmed its unscheduled downtime by 30% after it had implemented predictive analytics. This example indicates the advantages of using data-driven decision-making in the optimization of OT asset management.

Regulatory Compliance and Risk Management

Complying with regulations is crucial for OT asset management. Key regulations impact areas such as safety, environmental protection, and data security. OSHA, EPA, and NIST compliance is mandatory for a secure and effective operation. The creation of periodic audits, training, and fresh policies are just some of the integral elements that form a strong compliance program.

Managing the risk associated with OT assets is important for smooth operations.

The risk management techniques include risk assessments, mitigation plans, and contingency planning. Mitigating and protecting critical assets from associated risks involves implementing robust security measures and effectively monitoring these assets. If the risks are effectively managed in this way, there will be less disruption and more continuity in operations.

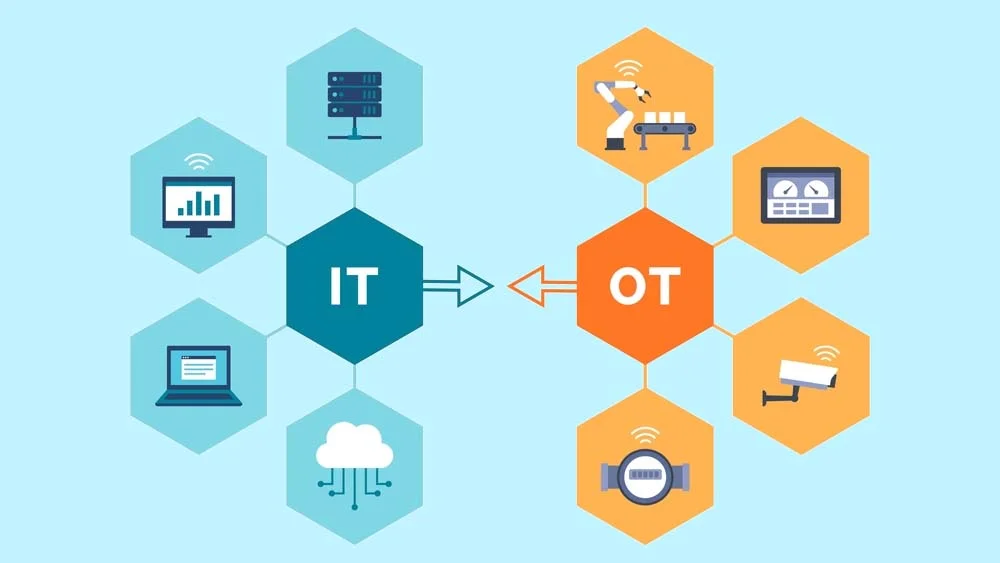

Integrate IT and OT for Better Asset Management.

Asset management can benefit immensely from the integration of IT and OT. Business and operational systems will flow smoothly to make more effective decisions. This includes integration strategies through middleware and common communication protocols among devices.

This sort of convergence offers advantages and benefits associated with enhanced operational visibility, better decision-making, and streamlined operations. However, these converged systems should be protected against cyber threats.

IT/OT convergence does not at all mean that critical assets are to be exposed by keeping them open while assuring a strong cybersecurity framework. This includes security measures with regard to firewalls, intrusion detection systems, and regular audits.

Adopt best practices to design a zero-trust model and train regularly to harden your defenses. IT and OT integration holds immense potential for efficiency improvement.

Better resource allocation, less downtime, and enhanced performance of assets demonstrate the impact on ROI created through IT/OT integration. Companies with an effective blend or merge of their IT and OT systems report improved operational efficiency and enormous cost savings.

Implementing Predictive Maintenance for Cost Reduction

Understanding the differences between predictive and preventive maintenance is crucial for maximizing returns on investment. It is more data-driven and can foresee issues before occurrence, while preventive maintenance occurs at periodic intervals.

Predictive vs Preventive Maintenance

Predictive maintenance can predict high ROI through reduced downtime, which is possible through data forecasting failures. At best, preventive maintenance can expect a moderate ROI, which consists of scheduled routine checks; sometimes, over-maintenance can occur.

Predictive Maintenance Technologies

Leverage IoT, AI, and Machine Learning to completely transform your maintenance strategies. With IoT sensors tracking the condition of assets in real-time, AI algorithms analyzing data for predictive insights, and machine learning that continues to improve predictive models, all these technologies make maintenance efficient and cost-effective with real-time insight and advanced predictiveness.

OT Asset Lifecycle Management Strategies

Managing OT assets through their lifecycle—from acquisition to disposal—requires various strategies for optimal performance and cost-efficiency. Acquisition, operation, maintenance, and disposal are major stages in the life cycle of an asset.

Acquisition involves choosing the right assets according to needs and budget. Efficient operation will ensure that the assets are well utilized, and regular maintenance will keep them in good order.

Proper disposal or recycling of non-serviceable and obsolete equipment is necessary and completes the life cycle. TCO assessment informs rational choices of asset management.

Acquisition, operation, maintenance, and disposal costs make up the TCO. Techniques for calculating TCO include NPV, IRR, and payback period. From these methods, a view of the overall cost of managing assets will emerge throughout their lifecycle.

Sustainability is increasingly integrated into asset lifecycle management. It not only reduces the impact on the environment but also aids in cost savings for organizations.

From energy efficiency and recycling to sourcing—all of these strategies contribute toward financial and environmental benefits. Sustainability enables an organization to promote its good image while offering long-term cost savings.

Training and Workforce Development for OT Asset Management

OT asset management skills require training programs for their betterment. Technical skills, along with soft skills, deal with comprehensive workforce development. Things like workshops, certifications, and on-the-job training help identify the most efficient methods of skill development. A few of the key skills will relate to technical proficiency, cybersecurity awareness, and data analysis.

In the context of evolving workplaces, OT workforce management requires strategic planning to address existing skill gaps and meet future needs. Strategies for workforce planning include succession planning, talent development, and continuous learning. This enables organizations to project and address workforce needs with the view of ensuring that they have the requisite skills to handle OT assets effectively.

Strategy |

Benefit |

| Data Analytics | Predictive maintenance and optimization |

| IT/OT Integration | Improved decision-making and efficiency |

| Predictive Maintenance | Reduced downtime and maintenance costs |

| Lifecycle Management | Cost-effective asset management |

| Real-time Asset Tracking | Enhanced operational efficiency |

| Regulatory Compliance | Reduced risk and ensured compliance |

| Workforce Development | Skilled workforce and improved management |

| Adoption of Emerging Technologies | Future-proofing asset management |

Successful training programs have improved OT asset management. For instance, following the execution of an end-to-end training program at a utility company, improves operational efficiency by 20%. These examples prove that investing in the development of your workforce pays off in better asset management.

Organizations should thus embrace the upcoming technologies in OT asset management and constantly innovate to stay ahead. Other steps to prepare include investment in new technologies, strategic planning, and a culture of continuous learning. Staying ahead of technological changes will help organizations in OT asset management to remain competitive with a sustained advantage and success.

Effective OT asset management can help maximize your ROI through data analytics, IT-OT integration, predictive maintenance, and much more. These strategies, including improved cost control and compliance, boost operational efficiency and increase ROI. Begin to optimize your OT asset management by following these best practices from day one.

FAQs

-

What is the difference between predictive and preventive maintenance?

Predictive maintenance uses data to forecast failures, while preventive maintenance follows a routine schedule.

-

How can IT/OT integration improve asset management?

IT/OT integration enhances visibility, improves decision-making, and streamlines operations.

-

Why is cybersecurity important in OT asset management?

Cybersecurity protects critical assets from vulnerabilities and ensures the integrity of integrated systems.

Incorporating these practices ensures a comprehensive and effective OT asset management strategy that maximizes your return on investment.