An efficient warehouse management system is a cornerstone of supply chain optimization. By streamlining processes and reducing errors, effective management enhances the overall performance and reliability of supply chains. Properly managed warehouses significantly impact supply chain success by increasing efficiency and reducing costs. Integrating advanced technologies like Warehouse Management Systems (WMS) ensures accurate inventory control and faster order processing. These systems, when combined with strategic locations such as a Los Angeles fulfillment center, help in minimizing delivery times. Collaboration with organizations offering full-circle fulfillment and distribution services can enhance your operations further.

For businesses aiming to outperform competitors, warehouse management plays a pivotal role. Implementing best practices in warehousing not only supports timely delivery but also ensures adaptability to market fluctuations, giving your supply chain a competitive edge.

Key Takeaways

- Efficient management boosts supply chain efficiency.

- Strategic locations reduce delivery times.

- Advanced systems improve accuracy and speed.

The Role of Warehouse Management in Supply Chain Efficiency

Effective warehouse management enhances supply chain performance by ensuring efficient inventory control, streamlined order processing, and leveraging cutting-edge technology. These components collectively contribute to greater logistics efficiency and improved customer satisfaction.

Optimizing Inventory Control and Storage

Efficient inventory control is essential for a successful supply chain. By implementing robust inventory management practices, you can maintain the right balance of stock levels and reduce overhead costs. Utilizing advanced tools like a warehouse management system (WMS) can offer real-time visibility and analytics, improving accuracy and space utilization.

Optimal storage design further aids in efficient inventory practices. Techniques such as storage optimization and an effective warehouse putaway process ensure that products are stored strategically, facilitating quick retrieval and minimizing wasted space. In addition to optimizing storage, conducting regular Gemba walks—where warehouse managers observe workflows directly on the floor—can help identify inefficiencies and areas for improvement. Utilizing a structured Gemba walk checklist ensures these observations are thorough and actionable, leading to more streamlined warehouse operations and better inventory control. Incorporating barcodes and RFID tags also enhances accuracy, reducing discrepancies in stock counts.

Enhancing Order Processing and Fulfillment

Speed and accuracy in processing orders are crucial for supply chain efficiency. Streamlining picking and packing processes ensures that products are assembled correctly and shipped promptly, leading to higher customer satisfaction. Warehouse management can integrate automation, like automated guided vehicles (AGVs), to expedite these operations.

Efficient order fulfillment processes also allow for better planning and delivery, minimizing delays. A focus on improving logistics through precise order tracking and handling small-to-large-scale orders efficiently is vital. This ensures that your customers receive their products on time, enhancing reliability and trust.

Leveraging Technology for Warehouse Operations

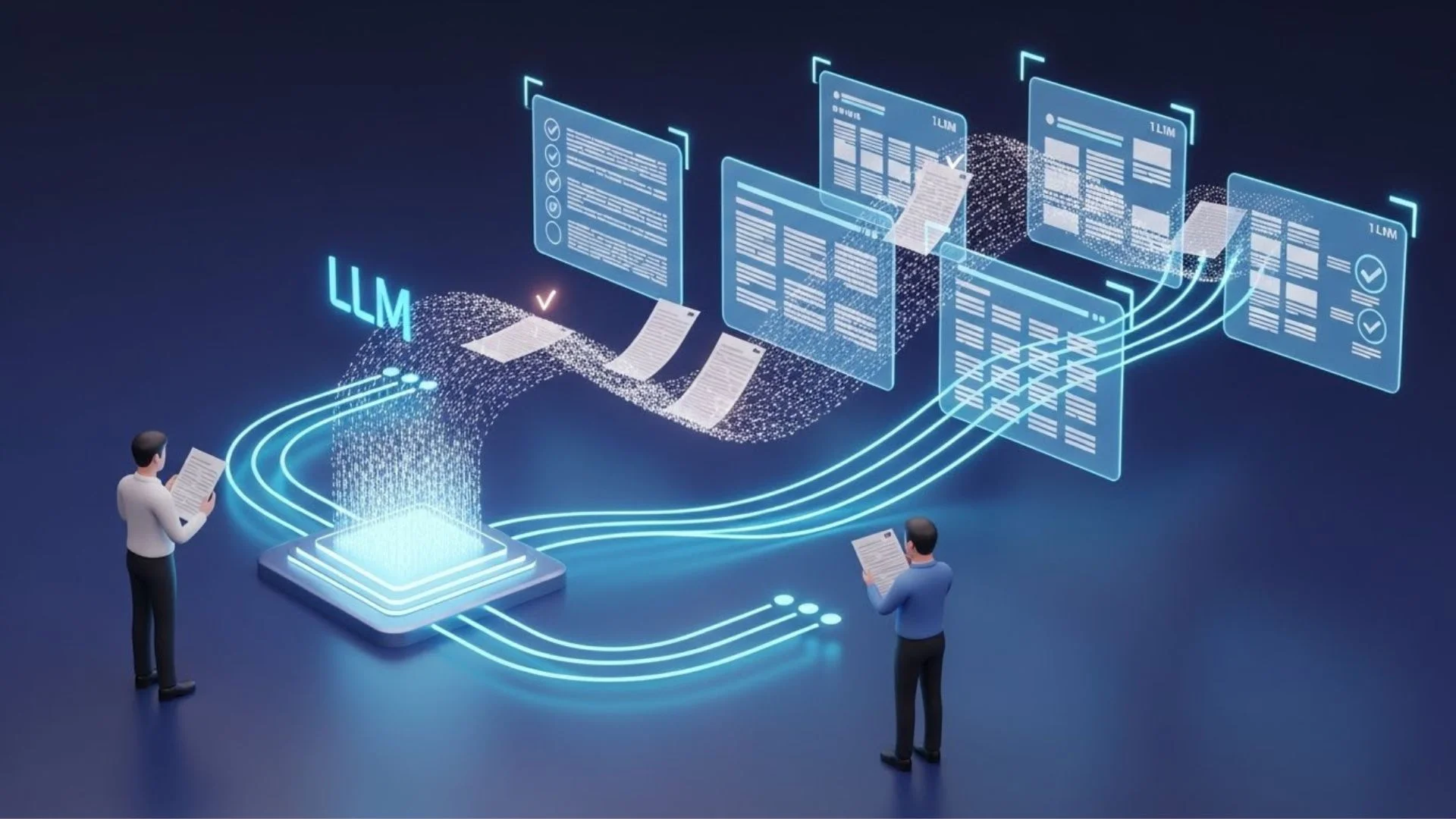

Technology integration in warehouse operations can dramatically boost performance and efficiency. Incorporating innovations such as the Internet of Things (IoT), advanced analytics, and automation tools offers superior visibility and control over every aspect of the warehouse. These technologies help in planning and optimizing daily tasks and long-term strategies.

Automation solutions, like AGVs and robotics, reduce manual tasks and errors, increasing overall productivity. Furthermore, adopting a robust warehouse management system links all components into a seamless operation. This use of technology creates agility in responding to market demands, while also lowering operational costs and enhancing customer satisfaction.

Influencing Supply Chain Performance and Competitive Advantage

Effective warehouse management is essential in reducing operational costs and increasing supply chain visibility, leading to a unique competitive edge. Strategic use of intelligence, sustainability practices, and enhanced decision-making processes enable businesses to stay agile and responsive in the competitive landscape of global trade.

Improving Cost Management and Financial Performance

Enhancing cost management in warehousing can lead to significant cost savings. By optimizing operational costs, like transportation costs and inventory holding expenses, you improve your financial performance. Implementing robust transportation management strategies ensures more efficient delivery routes, reducing unnecessary expenses.

Real-time tracking systems provide visibility into inventory levels, enabling better demand forecasting and reduced excess stock. This approach reduces storage expenses and allows you to allocate financial resources more effectively, enhancing your cost management efforts.

Advancing Strategic Decision Making and Responsiveness

Strategic decision-making is improved through predictive analytics and real-time data. These tools allow for analyzing trends and forecasting demand accurately. By leveraging this technology, you can enhance your agility and responsiveness to market changes.

Implementing advanced risk management strategies also contributes to swift and informed decision-making. An agile supply chain can respond promptly to disruptions, maintaining customer satisfaction and giving you a competitive advantage. Using these techniques ensures your business remains adaptable and strategically positioned.

Addressing Environmental and Social Considerations in Warehousing

Focusing on sustainability and reducing the environmental impact of warehousing operations is vital. Implementing green initiatives and energy-efficient practices in warehousing supports your supply chain sustainability goals.

Social considerations include improving working conditions, which enhances employee morale and productivity. Addressing both environmental and social impacts builds a reputable brand image and aligns with global sustainability standards. This approach not only meets industry regulations but also increases appeal to environmentally conscious consumers.

Conclusion

You can significantly improve supply chain efficiency through effective warehouse management. By focusing on streamlined processes, such as inventory management and order fulfillment, you enhance productivity and reduce costs. Implementing the right technologies, like advanced Warehouse Management Systems, enables accurate tracking and better utilization of resources. Prioritizing these can lead to a more resilient and responsive supply chain.