The manufacturing sector is always evolving, with asset management standing out as an area undergoing growth. In this article, we’ll delve into the future of asset management in manufacturing and how technological advancements in the form of industrial asset management software and changing industry trends are reshaping this domain.

1. Embracing Technology: The Emergence of IoT

Connectivity plays a role in asset management in manufacturing industry today. The Internet of Things (IoT) has transformed how manufacturers manage their assets by enabling time monitoring and data analysis. IoT sensors integrated into machinery can gather data on performance, maintenance requirements, and potential malfunctions.

This data empowers manufacturers to improve maintenance procedures by addressing issues proactively before they escalate into breakdowns. This not only saves time and resources but also reduces production interruptions and enhances overall efficiency, according to NRI Parts.

2. AI-Powered Analytics: Harnessing the Potential of Big Data

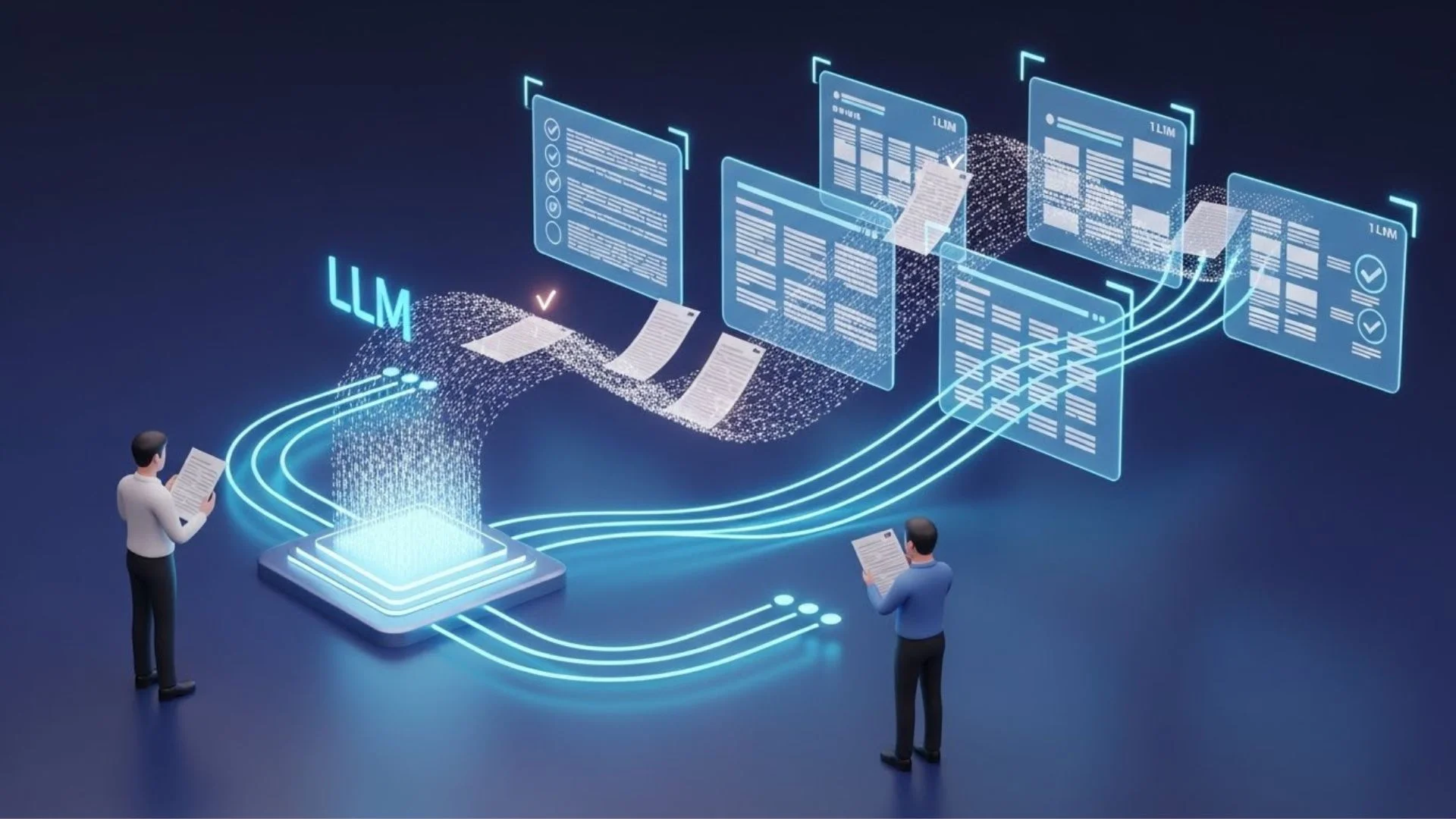

Technological progress has resulted in an abundance of data in the manufacturing sector. Artificial intelligence (AI) is being utilized to analyze large amounts of data effectively, enabling manufacturers to make more informed decisions regarding their assets.

Through AI-driven analytics, companies can pinpoint patterns, unearth hidden insights, and forecast asset failures with precision. Taking an AI approach allows manufacturers to plan maintenance while reducing unexpected downtime.

3. Remote Monitoring: Real-time Insights

Remote monitoring solutions have become essential in managing assets in manufacturing facilities. These systems enable the monitoring of factors like temperature, humidity, energy usage, vibrations, and more.

With remote monitoring capabilities, assets can be supervised from any location through a web-based interface or mobile app. Alerts can be generated for issues needing attention or immediate maintenance tasks. This leads to lower response times without the need to be physically present on-site—an advantage for efficiently managing distributed operations or involving external service providers.

4. Digital Twins: Facilitating Virtual Asset Management

The introduction of digital twins, a representation or duplicate of an asset that combines real-time data with advanced modeling techniques, has been a significant development in asset management.

Digital twins replicate how an asset behaves and performs under the circumstances, helping manufacturers optimize maintenance schedules, predict failures, and enhance efficiency. They provide insights into asset performance and enable proactive decision-making to maintain high productivity levels.

5. Data Security: Protecting Critical Information

As reliance on interconnected technology in asset management grows, ensuring data security is crucial. Manufacturing companies need to have cybersecurity measures in place to protect information from cyberattacks and unauthorized access.

Enforcing access controls using encryption protocols and implementing network monitoring solutions are components of safeguarding sensitive data generated by IoT devices and other connected assets. Manufacturers should adopt security frameworks to prevent disruptions throughout the value chain.

6. Industry 4.0: The Evolution Continues

The integration of technologies like IoT, AI-driven analytics, remote monitoring, and digital twins has given rise to Industry 4.0—a shift that merges manufacturing with these systems.

With Industry 4.0 advancing and gaining acceptance, centralized asset management becomes more achievable. This holistic approach enables manufacturers to view their assets’ lifecycles across locations and operational areas on a single unified platform.

7. Blockchain Technology: Improving Transparency and Traceability

Blockchain technology could revolutionize asset management in the manufacturing sector by enhancing transparency and traceability. Through the adoption of solutions, manufacturers can establish an unchangeable record of each asset’s journey from inception to its current status.

Using technology allows manufacturers to monitor an asset’s lifespan, including its maintenance history, changes in ownership, and any modifications made over time. This transparency facilitates auditing procedures, streamlines supply chain operations, and ensures adherence to regulatory standards.

Summary

The future of asset management in the manufacturing sector heavily depends on embracing progress. By utilizing capabilities for monitoring in time and employing AI-driven analytics for predictive maintenance strategies, manufacturers can enjoy enhanced efficiency, reduced costs associated with downtime, and increased overall productivity. This positions them as players in an evolving global marketplace.