In the ever-evolving landscape of product life packaging, efficiency, accuracy, and compliance stand as pillars of success. From ideation to distribution, every phase of the packaging journey demands meticulous attention to detail and seamless coordination. At the heart of this intricate process lies label management, a cornerstone element that ensures labels meet regulatory standards, convey vital information, and reflect brand identity accurately. This extensive exploration delves into the pivotal role of label management within the broader context of packaging management, shedding light on its significance and the transformative impact of online proofing tools.

Understanding Packaging Management

Packaging management is a comprehensive process focused on refining the creation, manufacturing, and dissemination of packaging materials. Also, it encompasses a diverse spectrum of responsibilities, spanning from crafting artwork to adhering to regulatory standards, managing supply chains, promoting sustainability, and engaging consumers effectively. The efficacy of packaging management is fundamental for bolstering brand recognition, upholding the authenticity of products, and adapting to the changing demands of consumers.

In essence, packaging management encompasses a wide array of tasks, each crucial for the success of a product in the market. Additionally, from designing visually appealing packaging to ensuring compliance with regulatory requirements, orchestrating efficient supply chain logistics, championing sustainability efforts, and devising consumer engagement strategies, every aspect plays a pivotal role in shaping the perception and reception of a product. As consumer preferences evolve and regulatory landscapes shift, effective packaging management becomes increasingly vital for brands seeking to differentiate themselves, build trust with consumers, and navigate the complexities of today’s marketplace.

The Significance of Label Management

Label management constitutes a vital component of packaging management, focusing on the creation, review, approval, and distribution of labels affixed to products. Labels serve as critical communication tools, conveying essential information such as ingredients, usage instructions, allergen warnings, and branding elements. Inefficient label management practices can lead to errors, compliance issues, and delays, undermining consumer trust and brand reputation. Additionally, An adhesive label manufacturer plays a key role in ensuring that labels are accurately produced and meet all necessary standards, helping to streamline the label management process and prevent potential issues.

Harnessing the Power of Online Proofing Tools

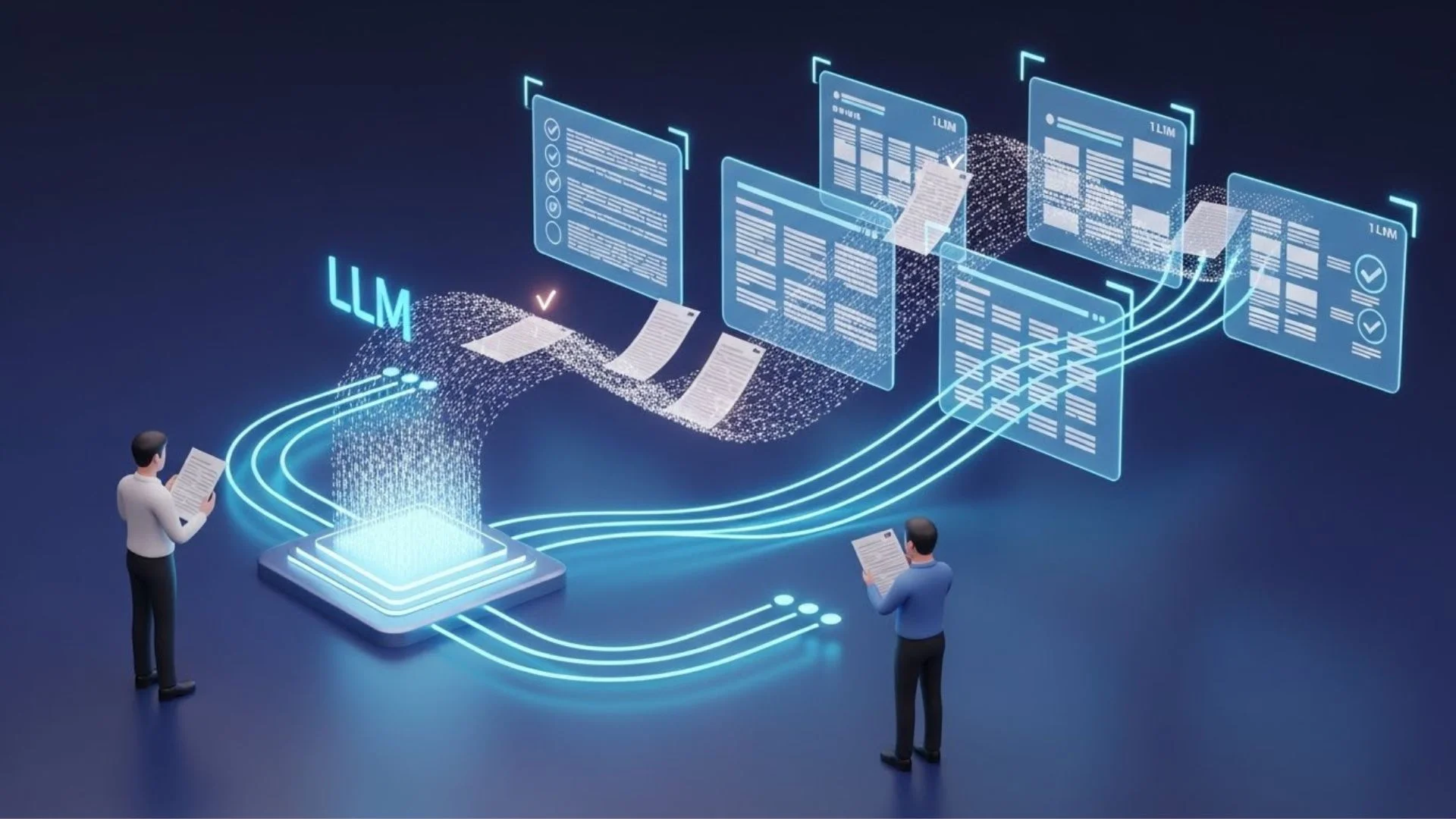

Online proofing tools play a crucial role in the domain of label management and broader packaging processes. These digital solutions serve as invaluable assets, offering stakeholders centralized platforms for seamless collaboration, remote review, annotation, and approval of label artwork. Facilitating a dynamic and efficient workflow, online proofing tools have become indispensable in modern label and packaging management.

By providing stakeholders with a centralized space, these tools transcend geographical barriers, enabling collaborative efforts regardless of physical location. The incorporation of essential features like version control ensures clarity in managing different iterations of label artwork. Real-time commenting fosters instant communication among stakeholders, facilitating swift decision-making and iterative improvements. Additionally, customizable workflows adapt to specific project requirements, optimizing the proofing process according to the unique needs of each label or packaging project.

The transformative impact of online proofing tools extends to streamlining the entire proofing process, enhancing communication channels, and ultimately expediting the time-to-market. As industries evolve and businesses adapt to digital workflows, these tools have emerged as essential catalysts for achieving accuracy, efficiency, and compliance in label and packaging management. Also, their role goes beyond mere convenience, becoming a linchpin in the quest for precision and agility within the intricate realm of label and packaging processes.

Key Benefits of Label Management in Packaging Management

1. Enhanced Collaboration and Communication

Label management platforms facilitate seamless collaboration and communication among internal teams, external partners, and clients. Also, online proofing tools enable stakeholders to provide feedback, suggest revisions, and approve artwork from anywhere, at any time. This streamlined collaboration reduces the need for in-person meetings, accelerates decision-making, and fosters greater transparency throughout the packaging lifecycle.

2. Accuracy and Compliance Assurance

Accurate and compliant labeling is essential to meet regulatory requirements and consumer expectations. Label management systems integrate regulatory guidelines, templates, and validation checks to ensure compliance with regional standards and industry regulations. Online proofing tools empower stakeholders to review labels meticulously, identify errors, and make necessary corrections before production, minimizing compliance risks and potential recalls.

3. Increased Efficiency and Productivity

Traditional proofing processes involving printed proofs and manual annotations are time-consuming and error-prone. Online proofing tools automate and digitize the proofing process, eliminating the need for physical proofs and streamlining revisions. Stakeholders can review artwork simultaneously, track changes in real-time, and expedite approvals, resulting in shorter production cycles and faster time-to-market.

4. Seamless Integration with Existing Workflows

Label management systems seamlessly integrate with existing packaging management workflows and enterprise systems. Such as product lifecycle management (PLM) software and enterprise resource planning (ERP) systems. For example, data from your product life management system helps streamline label updates by keeping all involved parties informed throughout the product lifecycle, ensuring a steady flow of accurate information. This integration ensures data consistency, eliminates duplicate efforts, and facilitates end-to-end visibility across the packaging lifecycle, from concept to consumer.

5. Cost Savings and Risk Mitigation

By reducing errors, minimizing rework, and accelerating time-to-market, label management systems contribute to significant cost savings for organizations. The elimination of manual proofing processes and the reduction of compliance-related risks translate into tangible financial benefits and a competitive edge in the marketplace. Additionally, by mitigating compliance risks and ensuring product accuracy, label management systems help safeguard brand reputation and consumer trust.

Conclusion

In conclusion, effective label management is indispensable for streamlining packaging processes, ensuring regulatory compliance, and maintaining brand integrity. Online proofing tools serve as catalysts in this endeavor, empowering stakeholders to collaborate efficiently, ensure accuracy, and expedite approvals. By embracing label management systems and online proofing tools, organizations can optimize packaging workflows. They can also enhance regulatory compliance, and deliver products to market faster and more effectively.

To stay ahead in the evolving packaging industry, organizations should invest in label management technologies and online proofing tools. These investments help companies remain competitive, reduce risks, and address the changing demands of consumers and regulations. With the right tools and strategies, businesses can simplify packaging processes, foster innovation, and strengthen consumer relationships in a dynamic marketplace. Leveraging label management and online proofing tools is key to unlocking new opportunities and achieving sustainable growth in packaging management.