In today’s interconnected and rapidly evolving business landscape, risk mitigation plays a critical role in the success of supply and chain management. Identifying potential risks and developing effective strategies to mitigate them is paramount for organizations aiming to maintain operational efficiency and meet customer demands. This article explores the importance of risk mitigation in supply chain management and highlights critical strategies for success.

Understanding common risks in the supply chain is crucial. Risks include supplier issues, delivery delays, or bankruptcies. Other risks involve fluctuations in customer demand. This can create challenges in inventory management. Unexpected events, like natural disasters, can disrupt the supply chain. Risks also stem from the increasing reliance on digital systems. For instance, data breaches, hacking, or ransomware attacks pose challenges. Political instability or trade disputes can also impact operations.

Assessing specific risks relevant to the business is a key step. It involves conducting an evaluation to identify risks. It also includes understanding the unique risks associated with the industry. This understanding helps develop effective strategies.

The assessment starts with examining the supply chain systems

This aims to identify potential risks at various stages of the supply chain. It’s crucial to identify vulnerabilities within the supply chain. Understanding these helps address them. It’s also necessary to evaluate dependencies within the supply chain. This helps identify critical areas where disruptions could have an impact.

The assessment should also consider the potential impact of risks on operations. This involves evaluating the consequences of disruptions. These could include production delays or increased costs. Once risks are identified, they must be prioritized. High-priority risks require immediate attention.

Mitigation strategies are an important outcome of the risk assessment

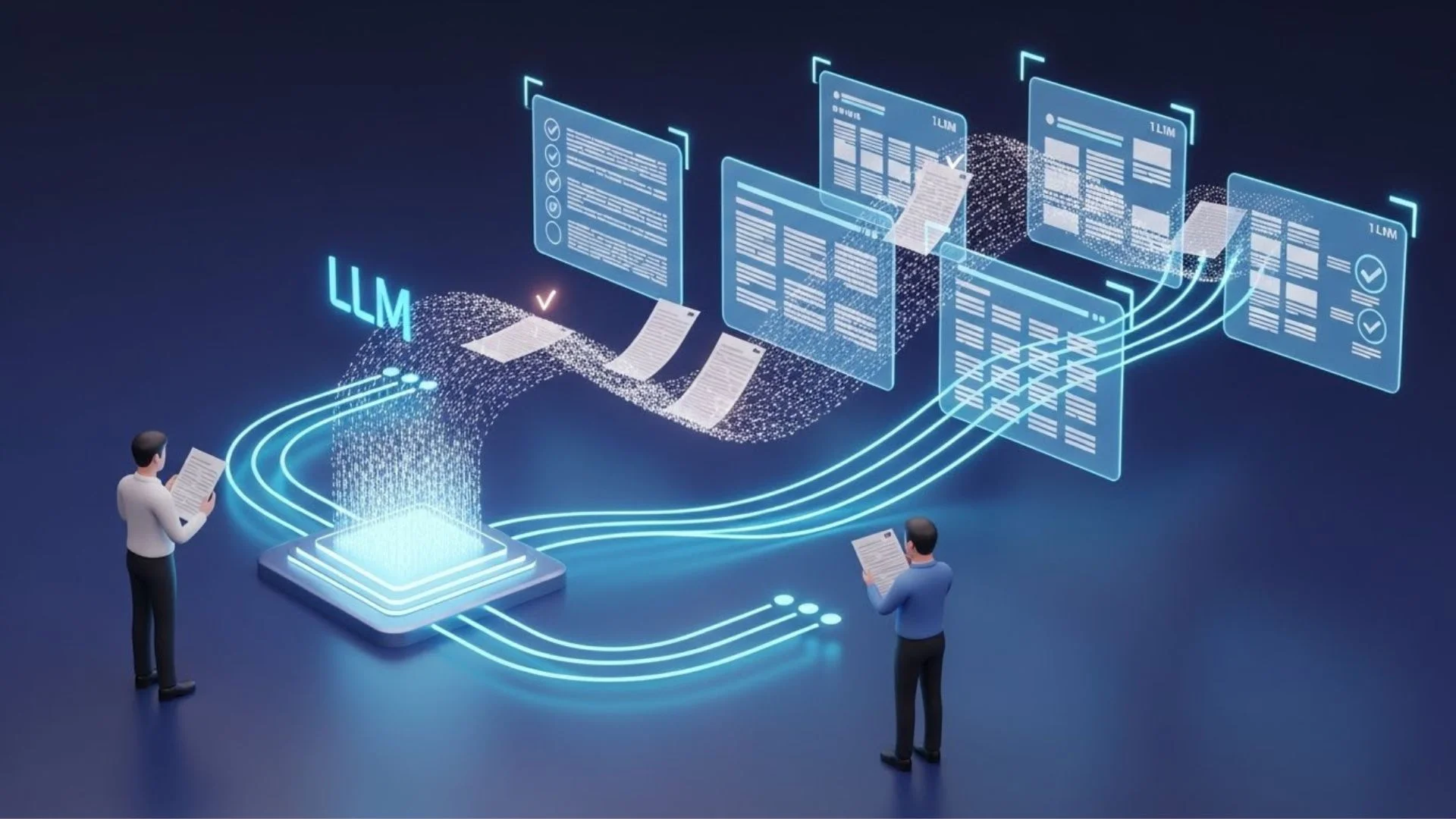

These can be developed based on the identified vulnerabilities and potential impacts. Approaches may include implementing backup plans or enhancing supply chain visibility. Effective strategies to mitigate supply chain risks also include the adoption of advanced technologies. For example, integrating AI in supply chain innovations can provide real-time insights and predictive analytics, which help anticipate potential disruptions and optimize operations. Leveraging AI-driven mailroom automation solutions transforms overall efficiency and adaptability, making it a critical component for modern supply chains.

Creating contingency plans helps respond to disruptions. This involves identifying potential risk scenarios. Redundancy planning is another key step. It involves establishing backup suppliers or alternative routes. Cross-training ensures that employees can adapt to challenges.

Proactive measures help reduce the impact of risks

These include establishing partnerships with suppliers. In the realm of proactive measures to mitigate supply chain risks, establishing robust partnerships with reliable suppliers stands out as a cornerstone strategy. John Geddes, Director of Sales at East Coast Storage Equipment, underscores the significance of such alliances, stating, ‘By fostering strong relationships with suppliers, companies can enhance their supply chain visibility and resilience. Our expertise in providing comprehensive storage solutions plays a pivotal role in ensuring the continuity and efficiency of supply chain operations, even in the face of unforeseen challenges.

Diversification is necessary to avoid overreliance on a single supplier. This involves identifying and qualifying additional suppliers. Effective communication among stakeholders is crucial. This involves engaging stakeholders in planning processes. It also requires establishing robust communication channels for information sharing.

Ongoing risk assessment is essential, given the dynamic nature of supply chain risks. This involves regular monitoring and analysis of supply chain key performance indicators. A culture encouraging innovation and continuous improvement is necessary. This could involve providing relevant training to employees. It also involves conducting reviews after disruptions. Adopting emerging technologies can also enhance capabilities.

Conclusion

By identifying risks and developing strategies, organizations can ensure long-term success. Building resilience and fostering improvement are also key to navigating uncertainties.